Discover various interesting information about Difference Between Hot Rolled Steel And Cold Rolled Steel, all of which we’ve summarized from various reliable sources.

The Essential Guide to Hot Rolled and Cold Rolled Steel: Unlocking Their Differences

As a passionate steel enthusiast, I’ve had the privilege of witnessing firsthand the transformative power of this remarkable material. From towering skyscrapers to sleek automobiles, steel has shaped our world in countless ways. And when it comes to steel, two distinct processes – hot rolling and cold rolling – play a pivotal role in determining its properties and performance.

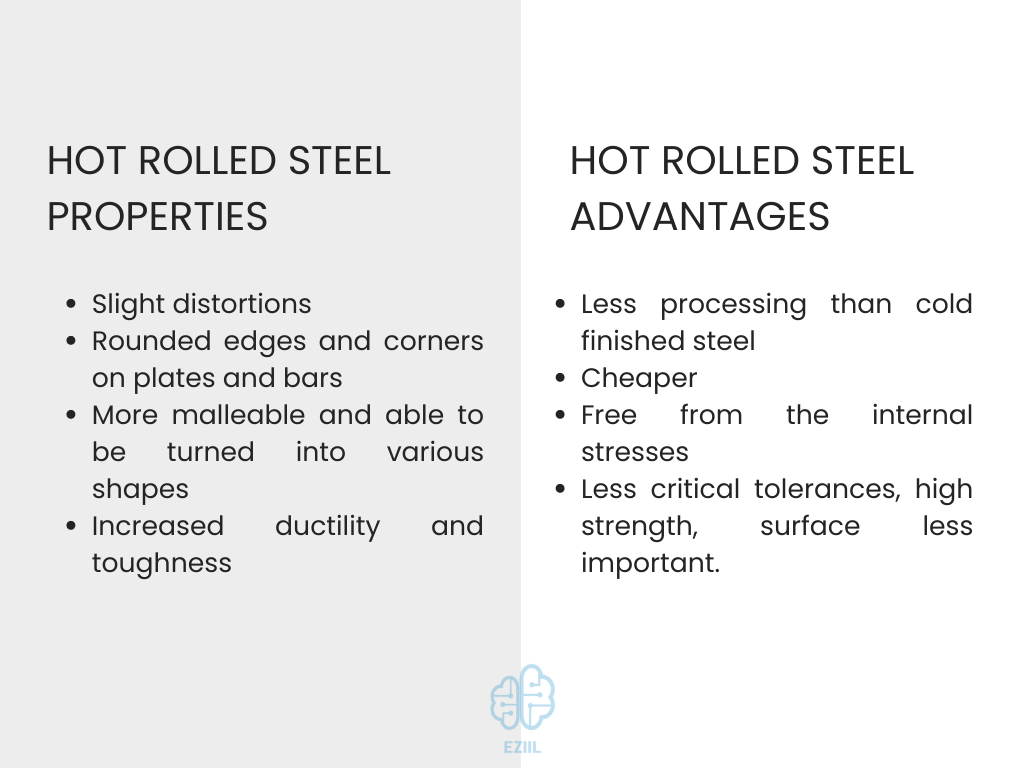

In the realm of steel production, hot rolling stands as a formidable technique, where steel billets are heated to scorching temperatures of approximately 2,300 degrees Fahrenheit. This intense heat renders the steel highly malleable, allowing it to be passed through massive rollers that shape it into various forms. Hot rolled steel, thus produced, exhibits a characteristically coarse surface texture and slightly lower strength compared to its cold rolled counterpart.

Delving into Cold Rolled Steel: Precision and Strength

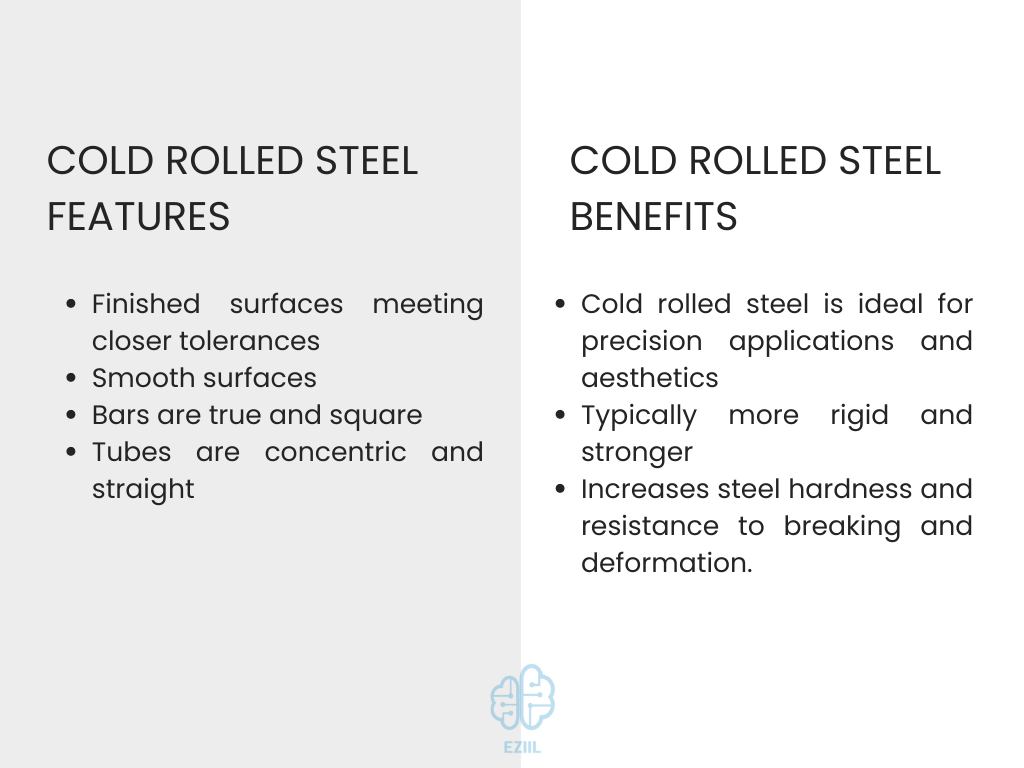

In contrast to hot rolling’s fiery embrace, cold rolling emerges as a more precise process. Here, steel sheets or strips are subjected to further rolling at room temperature. This cold deformation imparts exceptional strength and dimensional accuracy to the steel. Cold rolled steel boasts a smooth, lustrous surface finish and a superior tensile strength, making it an ideal choice for applications demanding high precision and strength-to-weight ratios.

Significance and Distinction: A Comparative Analysis

Hot rolled steel, owing to its inherent cost-effectiveness and ease of production, reigns supreme in structural applications such as I-beams, reinforcing bars, and heavy machinery components. Its rougher surface texture provides enhanced adhesion for coatings and paints, further increasing its versatility.

Cold rolled steel, on the other hand, excels in applications requiring superior strength, dimensional stability, and surface finish. Its smooth surface allows for seamless welding, making it prevalent in automotive, appliance, and construction industries. The enhanced strength-to-weight ratio of cold rolled steel enables the production of lighter yet more robust structures.

Embracing Innovation: Latest Trends and Developments

The world of steel is constantly evolving, with advancements pushing the boundaries of what this remarkable material can achieve. Hot rolled steel finds its niche in the construction of bridges, where its strength and durability endure the rigors of heavy traffic. Cold rolled steel, meanwhile, continues to transform the automotive industry as manufacturers strive for lighter, more fuel-efficient vehicles.

Beyond these traditional domains, steel innovation extends into the realm of advanced technologies. Hot rolled steel plays a vital role in offshore wind turbines, harnessing the power of the ocean for sustainable energy generation. Cold rolled steel finds application in aerospace, where its lightweight and strength contribute to the creation of high-performance aircraft.

Expert Advice for Navigating the Steel Landscape

As a seasoned blogger, I’ve gleaned valuable insights into the world of steel that can guide your journey. When selecting between hot rolled and cold rolled steel, consider the following factors:

- Cost and Availability: Hot rolled steel generally offers a cost advantage and wider availability.

- Strength and Precision: Cold rolled steel outperforms its hot rolled counterpart in terms of strength and dimensional accuracy.

- Surface Finish: Hot rolled steel exhibits a rougher surface texture, while cold rolled steel boasts a smooth, lustrous finish.

By carefully weighing these factors, you can make an informed decision that meets the specific demands of your project.

Frequently Asked Questions: Demystifying Hot and Cold Rolled Steel

Q: What is the primary distinction between hot rolled and cold rolled steel?

A: Hot rolled steel undergoes shaping at high temperatures, resulting in a coarse surface texture and lower strength. Conversely, cold rolled steel experiences shaping at room temperature, yielding a smooth surface finish and enhanced strength.

Q: Which process is more cost-effective, hot rolling or cold rolling?

A: Hot rolling generally offers a cost advantage due to reduced energy consumption and simpler production methods.

Q: Can hot rolled steel be used for precision applications?

A: While hot rolled steel may not exhibit the same level of precision as cold rolled steel, it can be employed in applications where dimensional accuracy is less critical.

Conclusion: Embracing the Strength and Versatility of Steel

Hot rolled and cold rolled steel stand as two indispensable pillars in the world of steel production. Their distinct properties and performance characteristics empower industries and shape our lives in countless ways. Whether it’s the towering strength of skyscrapers or the sleek precision of modern automobiles, the transformative power of steel continues to inspire innovation and drive human progress.

I encourage you to explore the fascinating world of steel further. Engage with forums, delve into industry news, and discover the myriad applications where hot rolled and cold rolled steel play a pivotal role. If you have any questions or insights to share, please don’t hesitate to reach out. Together, let us unlock the full potential of this extraordinary material.

Image: eziil.com

Difference Between Hot Rolled Steel And Cold Rolled Steel has been read by you on our site. We express our gratitude for your visit, and we hope this article is beneficial for you.